Bhutan-If the copper surface turns black by oxidation, the following measures can be taken to deal with it:

Washing and cleaning: gently clean the copper surface with mild soapy water or detergent and soft brush to remove dirt and oxide layer on the surface. Be careful not to use too rough brushes and strong acid cleaners to avoid scratching the copper surface.

Pickling treatment: soak the copper products in dilute hydrochloric acid or dilute acetic acid for several minutes, and then rinse them with clear water. This method is usually suitable for severe oxidation and can help to remove deeper oxides.

Use special products: There are some products specially used for cleaning and nursing copper products on the market, such as copper polishing paste and copper cleaning emulsion. These products need to be used correctly according to the instructions, which can effectively remove the oxide layer and protect the copper surface.

Prevention of re-oxidation: In order to prevent the copper surface from re-oxidation and blackening, a protective agent or wax can be sprayed on the surface. This can slow down the speed of oxidation and make copper products more durable.

It should be noted that the oxidation blackening of copper surface is a natural phenomenon, which is inevitable in the process of long-term use. Therefore, it is very important to clean and maintain copper products regularly.

There are many ways to polish copper, and the following are the common ones:

Manual polishing: Use sandpaper, abrasive cloth, polishing paste and other materials to manually polish copper products. This method requires patience and skill, but it can control the polishing effect more finely.

Chemical polishing: copper products are soaked in acidic or alkaline solution, and the oxide layer and dirt on the copper surface are removed by chemical reaction. This method does not need mechanical or manual operation, but it needs to pay attention to safety to avoid harm to human body and environment.

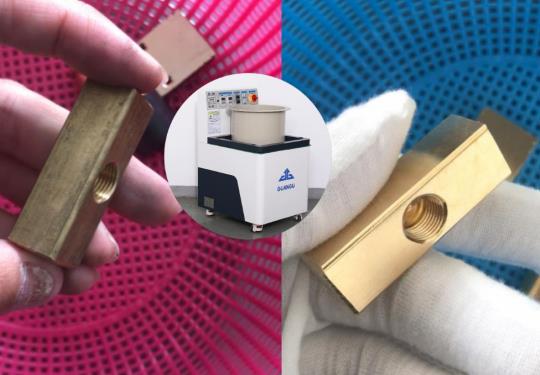

Mechanical polishing: Use grinding wheel, grinding head, grinding plate and other mechanical equipment to polish copper products. This method is faster, but it requires certain professional technology and equipment, and it is easy to produce scratches.

Electrolytic polishing: copper products are used as anode, and DC current is applied to the electrolyte to make the copper surface undergo redox reaction and remove oxide layer and dirt. This method is suitable for high-demand polishing occasions, such as bronze carving and antique restoration.

It should be noted that the surface of copper should be cleaned before polishing to remove dirt and oxide layer. At the same time, different polishing methods need to select suitable materials and tools and carry out them in the right way.

Wechat

Wechat