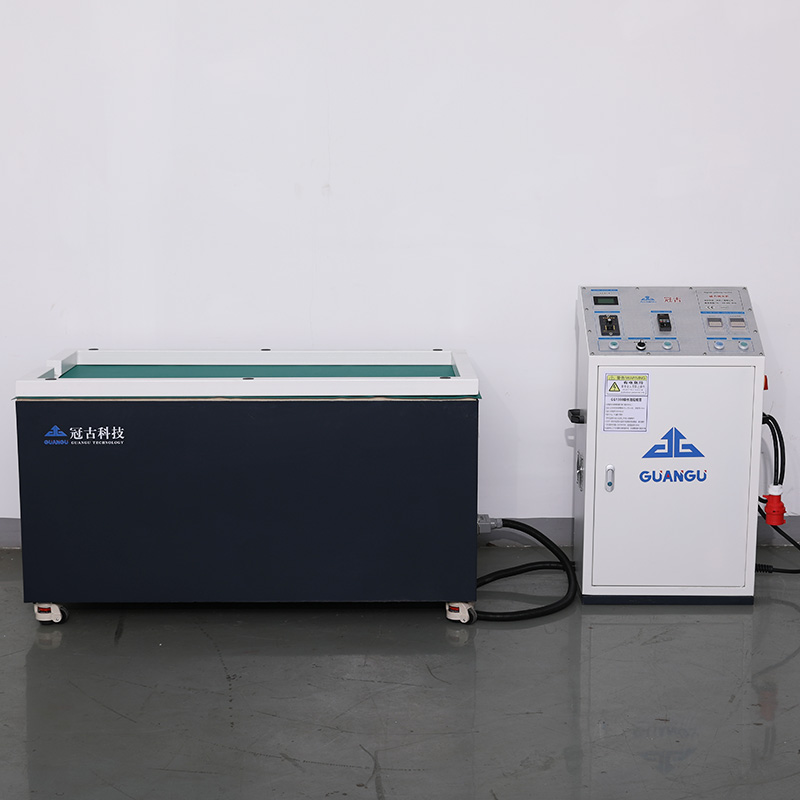

Bhutan-Guanguu Magnetic grinding machine name: GG1980, this equipment is customized, basic information is as follows:

Dimensions: 1980*720*1088

Grinding groove size: 1800*520mm(square bucket)

Power supply: AC380v

Motor power: 4kw*2

Equipment weight: 580Kg

Grinding capacity: 40-60Kg

Operation mode: positive and negative rotation and translation

Magnetic grinding steel needle: the material is imported SUS304 stainless steel, specification diameter: 0.2-2.00mm.

Lapping liquid: 100L

Motor speed: 1400 RPM

2 frequency converter control panel (Delta brand)

Polishing machine panel introduction

- Voltage display meter: The normal display is about 380v after startup.

- Reduction motor control panel: control the speed of magnetic field moving in the equipment.

- Inverter control panel: control the speed of Siemens main motor rotation.

- Positive and negative rotation time: control the time of positive rotation and reversal of the magnetic field.

- Total time: the total time the product needs to be ground

- Restart: After grinding the product for one time, if you need to restart the timing, press it directly.

- Switch: After the product is put away, press the switch and the equipment will start to work.

- Manual switch: It can manually adjust the position of the magnetic field in the equipment, so as to use the drum for grinding and polishing.

Guanguu magnetic polishing machine is an excellent surface treatment equipment, can meet the surface treatment needs of different industries, is the ideal choice to improve production efficiency, improve product quality.

Wechat

Wechat